Case Study – Woodbastwick Road – Blofield

Which Claret Civil Engineering business are you?

IMR WR Alliance – Whitlingham

Which department is this referring to?

Claret Lining Division

Who was the customer (only if you want them to feature in the article)?

Anglian Water IMR WR Alliance

What was the problem?

IMR WR Alliance were contacted by a dog walker who lives near to Woodbastwick Road in Blofield. They reported that a manhole appeared to be spilling over its frame and cover into a wooded area when walking nearby. The information was then passed over to the planning team who quickly sent a Claret Civil Engineering reactive team to investigate. Upon investigation, the manhole that was called in causing the issue was lifted and it had surcharged. The priority was to clear whatever had caused the blockage and then survey the sewer network; this had been completed within 3 hours of the complaint. This concluded that the sewer had indeed lifted in its inverse thus causing a blockage to occur with a build-up of rag or debris. This was then dug down and repaired. Further investigation of the sewer network on the same run was proven to be failing due to hydrogen sulphide attack of the concrete foul sewer. This was then handed over to the Lining Division at Claret Civil Engineering to provide a preventative collapse solution to stabilise the existing asset with a trenchless technology.

What was the resolution? Please include statistics and measurements if appropriate.

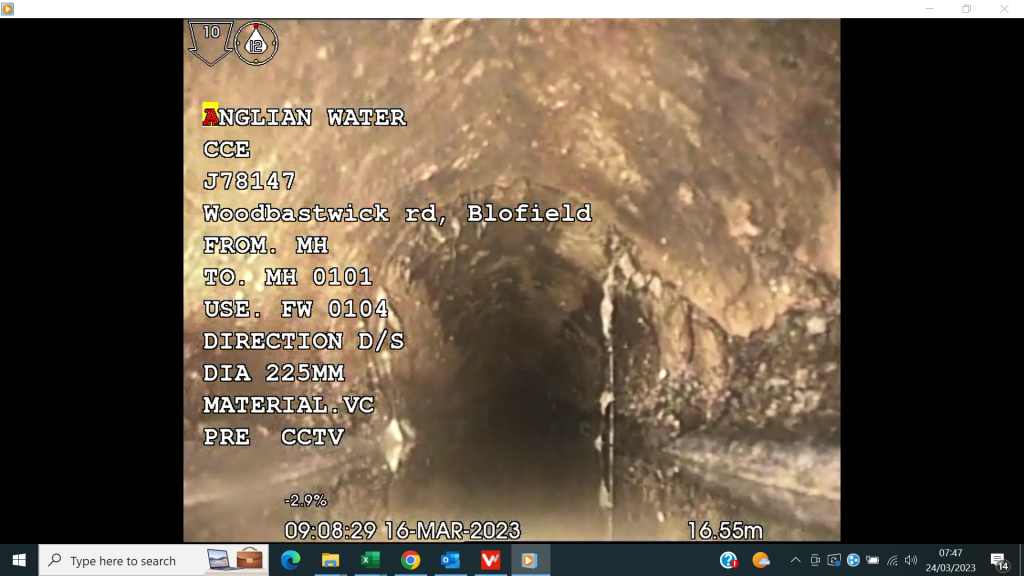

The surveyed length of sewer that was failing 138m x 225mm concrete pipe that had been corroded heavily and all joints were failing and even showing large holes and splits, joint seals were protruding into the sewer and heavy cracking through the 138m run.

Straight away, the lining management after reviewing the CCTV data, realised that a method to be used, would have to maintain a constant pressure of the new lining during the installation process. The lining division had a temporary scaffold design drafted and approved to build a launching platform from a tower for the lining to create a constant head of pressure during the lining installation. A method long used and tested for over 50 years and ideal in these circumstances. The materials used would be a polyurathane coated felt liner designed at 6mm thick, impregnated with a Water Research Centre approved Epoxy Resin.

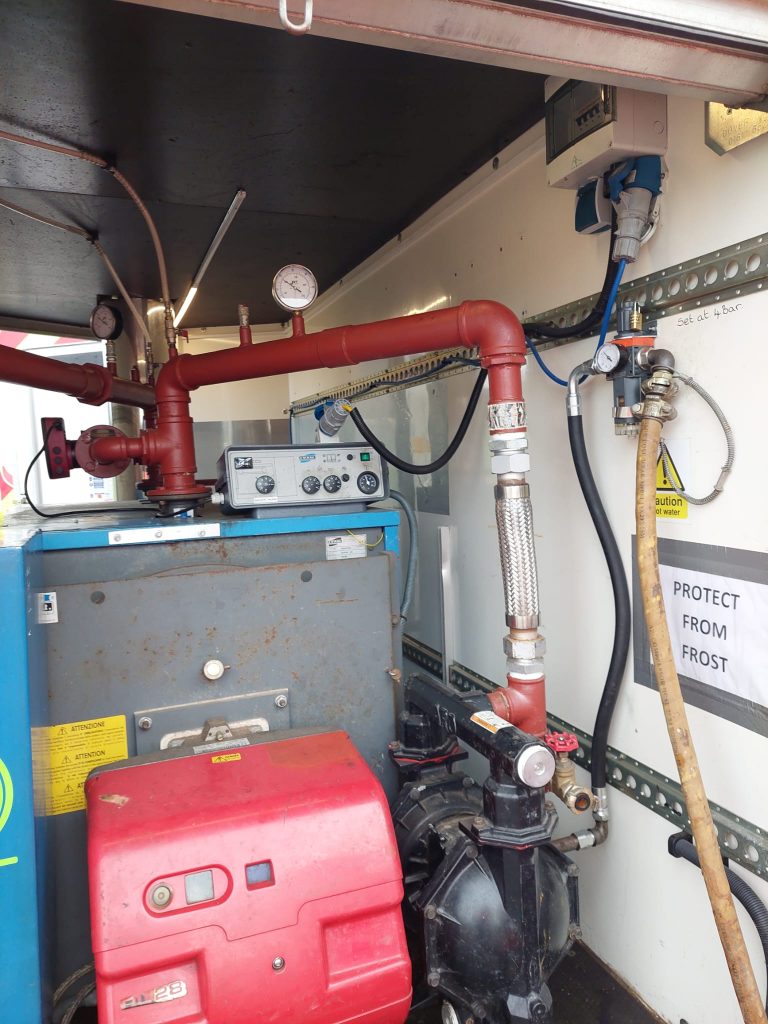

A five-way traffic light set-up was installed to accommodate the plant, equipment & materials, the sewer network residual flow was taken out of service with a temporary overland bypass for the duration of the works giving the lining installation team a dry sewer. The scaffold was then built, the liner installed with final effluent (recycled water), the cold water was then heated and boiled through a lorry mounted boiler for a 6-hour period then suitably cooled down with cold water. The newly made pipe was released of the water, the liner ends removed and the sewer network was restored giving the network a new jointless asset that would increase flow velocity by up to 30%, less impact on the environment and making huge carbon savings.

Claret pride themselves with the knowledge of delivering all aspects of sewer rehabilitation with all known methods of installation and have great understanding of material capabilities. If you require your sewer asset rehabilitating, then please contact our lining division on 01284 333222 or email Scott Weston on sweston@claretce.com